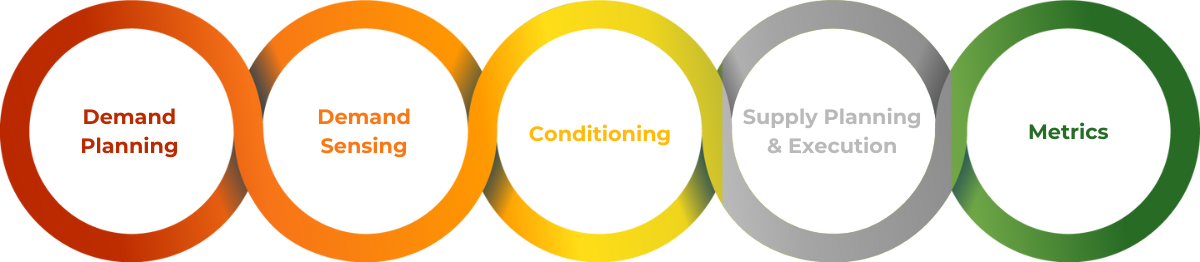

Reduce forecast error with smarter demand planning/sensing and conditioning

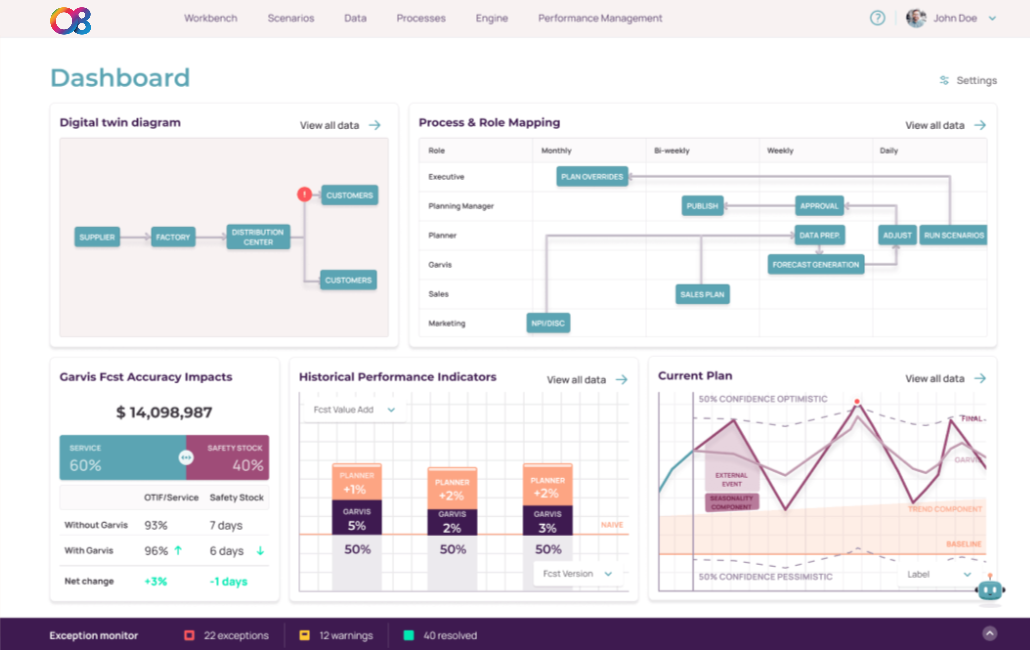

O8’s enterprise planning platform delivers supply chain stability quickly and cost-effectively with a combination of incredibly powerful and effective planning capabilities backed by a huge array of key functionality. Market strategies, demand patterns, product life cycles, and service policies to supply chain policies and stocking strategy.

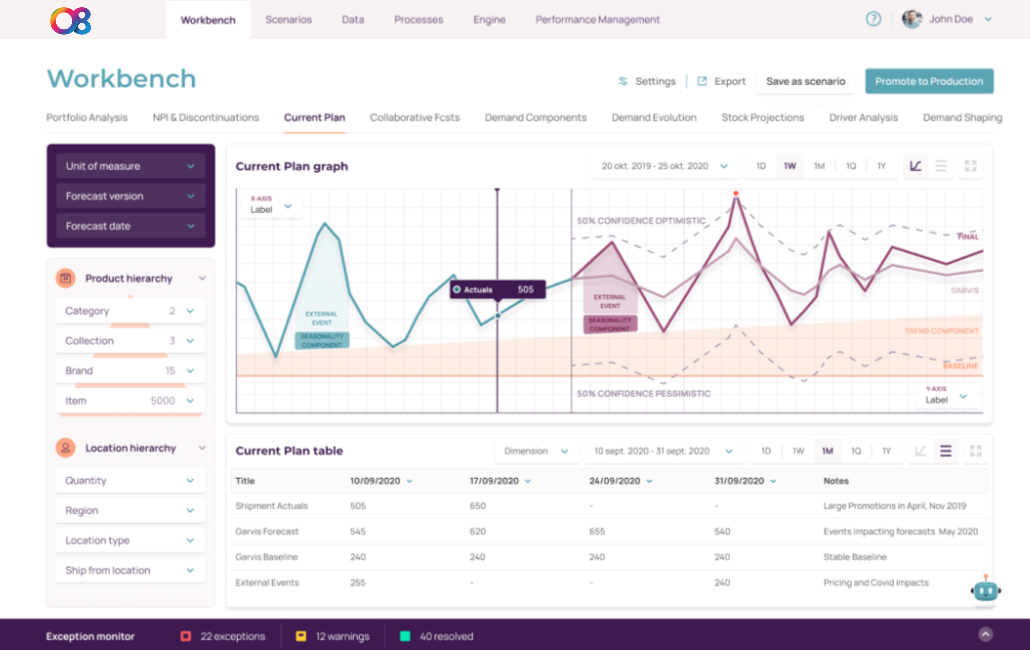

Leverage sources of insight to enhance and or validate trend and plan. O8’s internal data wrangler make integration to virtually and data source quick and easy.

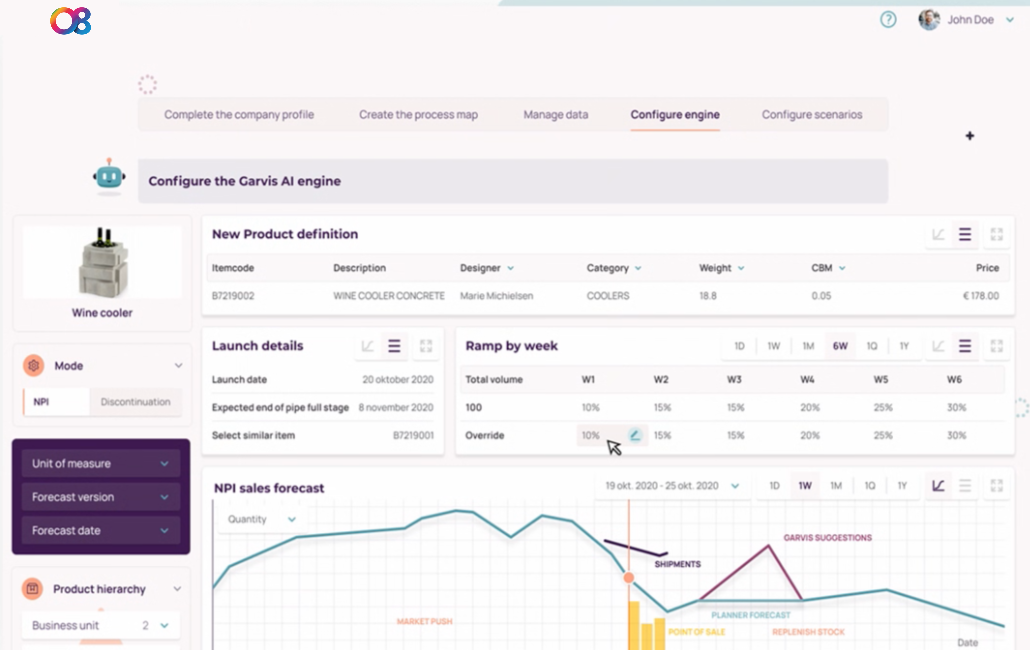

Set planning parameters to resolve constraints and compliment operating processes. Conditioning identifies the optimal of the 7 planning methods at the SKU level. Leverage O8’s digital twin capability to test your ability to achieve your plan and produce a tactical plan that will execute the requirement.

Planners release & manage orders in lead-time with full capacity and material availability checked. Complete shipment, factory, and supplier execution constraints managed and addressed.

Click here for more information on Supply Planning & Execution.

Fully integrated business intelligence and analytics deliver clarity in performance measurement and analysis supporting compliance and refinement of process.

Demand Planning / Sensing AND CONDITIONING

Solve the problems of planning in ERP.

Fear of Being Wrong

Fear of being wrong means individual demand planners often inflate forecasts which can drive excess inventory and higher carrying costs. This happens because MRP assumes a precisely wrong forecast to precisely raise planned orders and set predictive levels of safety stock. This pushes extra inventory, effort, and cost into safety stock.

Too Much Data, Imperfect Models

Planners must simplify the complex, define priorities, and act. Legacy planning methods overwhelm, making it increasingly difficult to be accurate and effective. As a result, CAPEX and inventory levels are increasing while service levels continue to decline.

Inadequate ERP Planning Functionality

The expense of ERP means that incomplete supply planning functionality is rarely questioned. Decision-making on such large investments means that supply planning requirements are often too low in any pecking order to materially impact any strategic platform choices.

The Curse of MRP

For 50 years, a one-size-fits-most MRP blurs the line between planning and execution. Planners are asked to replan and chase orders daily as MRP “shuffles the order pack” each time it runs. It is vital to separate the activity associated with planning from daily execution.

Get out of reactive mode

Change your planning method. Change your outcomes.

O8 supply chain conditioning de-risks forecast error and transforms S&OP into a reliable and executable tactical plan that reduces CAPEX and inventory levels while dramatically increasing fill rates and service levels.

Implementing traditional demand planning software is complex, expensive, and time-consuming. Orchestr8 does it in 24 hours. We combine your insights and your experience with Artificial Intelligence. This process allows you to reduce your forecast errors by up to 30% – usually within 24 hours of implementation. After that, forecast accuracy continues to improve as your planners improve and adjust and fine-tune their approach.

Manage Unpredictable Demand…Predictably

Better Understand Your Customers

Put Planners in Control of…well…Planning

Reduce forecast error and shrink inventory with orchestrated supply and demand planning

Predicting the future behavior of customers is the single biggest concern among CEOs…especially if the customer has another way to buy what he or she needs.

Unfortunately, fear of being wrong means individual planners often inflate forecasts which creates excess inventory and higher carrying costs. This happens because MRP consumes a precisely wrong forecast to precisely raise planned orders and set predictive levels of safety stock. This pushes extra inventory, effort, and cost into safety stock.

Orchestr8 puts the planner in control to reduce forecast error by up to 30% – usually within 24 hours!

Want to learn more? Request a copy of the Orchestrated Supply and Demand Planning product overview.

Request a copy of our planning overview and learn how to reduce forecast error by up to 30% – usually within 24 hours.

Sunsetting APO: A Cow in a Tracksuit Doesn’t Run Any Faster

SAP’s APO is riding into the sunset. What choices are available to replace the APO system?

Put the Planner in Control of…well…Planning

Learn how to reduce forecast error and shrink inventory with orchestrated supply and demand planning.

Reduce Forecast Errors by 30% to 40%

Get the white paper and learn how your planners will reduce forecast errors by 30% to 40%.