Minimize carrying costs, increase fulfillment turn rates,

decrease obsolete inventory by up to 90%

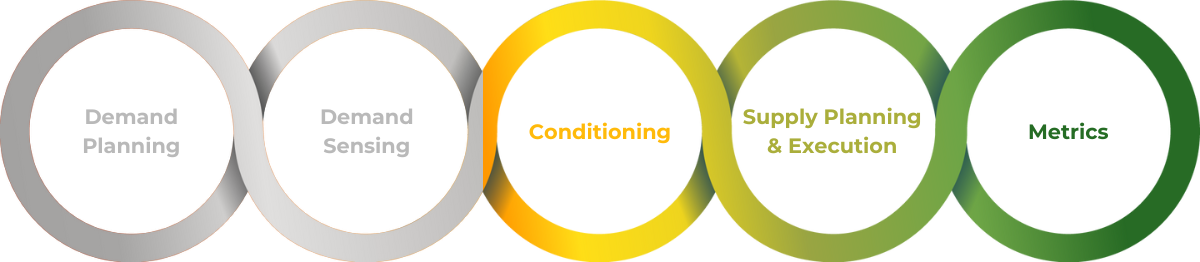

O8’s enterprise planning platform delivers supply chain stability quickly and cost-effectively with a combination of incredibly powerful and effective planning capabilities backed by a huge array of key functionality. Market strategies, demand patterns, product life cycles, and service policies to supply chain policies and stocking strategy.

Leverage sources of insight to enhance and or validate trend and plan. O8’s internal data wrangler make integration to virtually and data source quick and easy.

Set planning parameters to resolve constraints and compliment operating processes. Conditioning identifies the optimal of the 7 planning methods at the SKU level. Leverage O8’s digital twin capability to test your ability to achieve your plan and produce a tactical plan that will execute the requirement.

Planners release & manage orders in lead-time with full capacity and material availability checked. Complete shipment, factory, and supplier execution constraints managed and addressed.

Fully integrated business intelligence and analytics deliver clarity in performance measurement and analysis supporting compliance and refinement of process.

SUPPLY CONDITIONING AND PLANNING

Problems achieving supply chain performance? Maybe technology isn’t the problem?

Maybe the problem is your method.

Ownership of the supply chain has shifted from ops to IT under the belief that ERP technology is the solution for every challenge.

The inventory planning process is broken. Supply chain operations need to move beyond a one-size-fits-all approach to planning. Unlike ERP-based planning tools, O8’s enterprise planning platform delivers supply chain stability quickly and cost-effectively with a combination of smarter processes plus incredibly simple and effective planning tools backed by a huge array of key functionality.

So much of the supply chain is centered upon inventory. If you get your inventory planning right, most problems disappear. It should be obvious, after millions of dollars invested and years of technology implementations, that current software solutions don’t do what they need to do because supply planners are still using spreadsheets.

Instead of technology, it’s time to focus on the fundamentals. O8 strengthens your fundamentals with a proven process for end-to-end supply conditioning, planning, and execution – and guarantees amazing outcomes.

Supply Conditioning and Planning

Change your planning method. Change your outcomes.

How does it work?

At Orchestr8, we help companies overcome high inventories and poor service levels with supply and replenishment plans that practically eliminate the need for manual intervention and expediting. Our customers enjoy epic improvements in supply chain performance using an intelligent alternative that creates and executes agile supply plans that quickly respond to market changes.

End-to-End Supply Conditioning and Planning

A globally proven and scalable suite of planning capabilities for procurement, production, and warehousing. O8 is a single platform with end-to-end capabilities.

Improve stability and better balance demand and supply

Improve supply chain stability and forecast accuracy with the ability to create, save and manage a forecast that honors both pull (replenishment) and push (promotional or seasonal) demand.

Link inventory policy to product strategy and service goals

Fully compatible with Lean Manufacturing and Six Sigma initiatives, O8’s integrated business planning approach uses demand-pull principles to replenish inventory levels while linking inventory policies to product strategy and service goals.

Connect market strategies and demand patterns to execution

O8 directly connects market strategies, demand patterns, and service profiles to supply chain policies and operations. Best-practice inventory management techniques segment the planning process according to an item’s demand profile.

Reconnect inventory with operating capability

Increase S&OP success by breaking the dependency on inaccurate forecasts and re-connecting inventory with operating capability.

Conditioning

O8’s unique conditioning capability differentiates O8 from other vendors.

The S&OP process manages the longer-term horizon and undertakes specific tasks:

- Long term strategy review

- Tactical supply chain set up: promotions, life cycle changes, and policies using digital twin simulations

- Inventory & Capacity plan: Set capacity and inventory plans by SKU for the supply chain, including buffers against policies

Operational planning manages the process between the tactical and execution time horizon:

- The objective is to eliminate MPS and release orders in priority order in a way that the execution capability of the business can manage efficiently and effectively.

- To do this, some elements of setup need to be reflected in the Inventory plan, some are handled purely in the operational planning time horizon.

O8’s S&OP delivers more realistic results. Reaching beyond traditional supply and demand planning to consider daily operating constraints, including production, materials, and shipping.

Conditioning in O8 delivers a balanced plan to deliver business goals

- Segments the planning process according to an item’s demand profile (a plan for every part).

- Accommodates a diverse range of items, production rhythms, geographies, and markets.

- Policy-driven and refined monthly

- Integrates and extends the planning process to the rest of the business and beyond.

- MRP not required

Supply Planning

O8 accommodates a diverse range of items, production rhythms, geographies, and markets.

O8 Supply Manager leverages knowledge from Theory of Constraints (TOC), traditional MRP & DRP, Six Sigma, Lean and Flow and has been certified as fully compliant by the Demand Driven Institute. O8 even provides supplier portals for better synchronization with suppliers.

Planning Strategies include:

- Buffer (DDMRP): DD Buffer logic is replenished using the DD net-flow calculation on a daily basis

- Cyclic Buffer (ROC): as with DDMRP but with a cyclic revisit defined

- Flow (Rate Based): a flow rule combining DD and push logic to align continuous supply to consumption

- Low Volume: A ROP rule using a Poisson statistical model suited to items where usage is very low yet the item is critical in terms of availability

- Two Bin (Value): A ROP Poisson approach suited to low-value items where detail planning is not relevant. The stock is set to a $ coverage (e.g. consumables)

- MTO/RTO: a formal planning rule to support, make or buy to order where the service policy and/or lead time allow

- Forecast Error Percentage: uses a segmented FEP logic to calculate a time-phased safety stock when operating a make to forecast supply chain

Supply Planning Functionality

Volume Variability Analysis (VVA)

Digital Twin Simulation

Capacity Planning

Capacity Check

Materials Check

Sequence Groups

Promotions/Events Management

Production Wheels & Cyclic Ordering

Multi-Supplier Sourcing

Date-Effective Sourcing

Supplier Shutdown Management

Automated Order Release

Phase In/Phase Out

Substitutions

‘Big Order’ Management

Supplier Portals

Booking In Calendar

Supplementary Data Functionality

Ordering Groups

Automated Shipment/ Load Building

Quota Management

ABC Analysis

Transport Lane Optimization Shipment Building

Analytics Package

Orchestrated supply and demand planning is less than 120 days away

Delivered at a fraction of the cost of traditional supply chain software, Orchestr8’s enterprise planning platform:

- Honors both pull (replenishment) and push (promotional or seasonal) demand.

- Uses demand-driven supply planning and inventory management techniques that segment the planning process according to an item’s demand profile.

- Includes demand planning/sensing and conditioning to set up rules and policies and refine monthly.

- Speeds the planning cycle, including supply chain simulation and what-if analysis that helps eliminate manual intervention.

- Offers complete support to inventory planning processes including events, life cycle planning, capacity planning, and multi-tier planning.

- Provides enterprise-class capabilities that support multi-lingual and multicultural global implementations.

O8 is used at hundreds of locations around the globe. O8 connects market strategies, demand patterns, and service profiles to supply chain policies and operations, providing well-conditioned supply chains that result in dramatic inventory and service level improvements.

Want to learn more? Get in touch and learn how O8 can be up and running in 120 days.

Sunsetting APO: A Cow in a Tracksuit Doesn’t Run Any Faster

SAP’s APO is riding into the sunset. What choices are available to replace the APO system?

Put the Planner in Control of…well…Planning

Learn how to reduce forecast error and shrink inventory with orchestrated supply and demand planning.

Reduce Forecast Errors by 30% to 40%

Get the white paper and learn how your planners will reduce forecast errors by 30% to 40%.